| Client: UK-based fired heater simulation & engineering services provider | |

| Project Duration: 14 Weeks | |

| Location: USA | |

| Value: Not disclosed |

Detail Engineering & Design Activity for Fired Heater

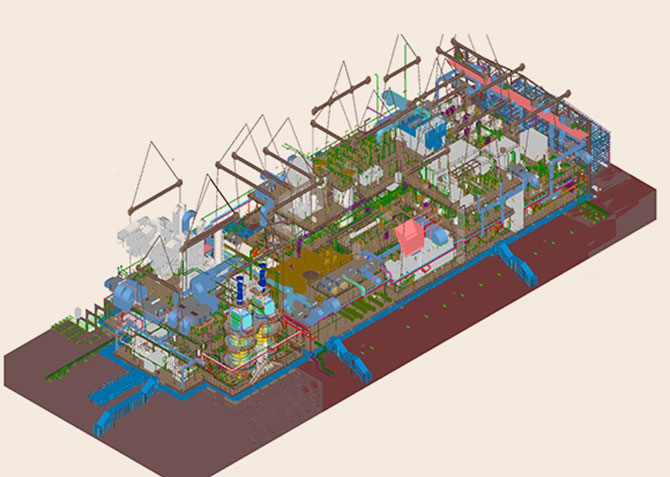

Overview. Detailed engineering for a direct-fired heater module used to maintain ethylene glycol temperature at a seawater treatment facility in Alaska. The heater module was fabricated and mounted on a barge for transport prior to integration into an onshore waste-heat recovery unit.

Scope of Work. 3D modeling (CADWorx & Tekla), piping stress analysis (CAESAR II), structural analysis (STAAD.Pro Connect Edition), design reviews and improvement recommendations, schedule & specification compliance, and project coordination.

Key Deliverables.

- Native 3D model & heater GA drawings

- Piping and structural analysis reports

- Structural fabrication drawings

- Lifting & transportation drawings

- Foundation load and anchor bolt location drawings

- Coil detail drawing

- Structural & coil bill of materials (MTO/BOM)

Tools & Software. CADWorx, Tekla, AutoCAD, STAAD.Pro Connect Edition, Navisworks, CAESAR II, MS Office.